PRODUCT PARAMETERS

Description

Introduction to towed Dragline Excavator Large Long Carbon Steel Forging Machining Transmission Spur large Gear Shaft

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Dragline Excavator Large Long Carbon Steel Forging Machining Transmission Spur large Gear Shaft refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Dragline Excavator Large Long Carbon Steel Forging Machining Transmission Spur large Gear Shaft

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Dragline Excavator Large Long Carbon Steel Forging Machining Transmission Spur large Gear Shaft)

Specification of Dragline Excavator Large Long Carbon Steel Forging Machining Transmission Spur large Gear Shaft

Dragline Excavators: The Ultimate Heavy-Duty Excavator with Long-Range Reach and Large Capacity

Are you in search of the perfect excavator for your construction projects? Look no further than our Dragline Excavators, equipped with long-range reach, high-quality materials, and extensive capabilities.

One of the key features of our Dragline Excavators is their impressive length, measuring up to 14 feet (4 meters) in width. This extended reach allows you to performExcavations in areas that may be too challenging or dangerous for traditional excavators.

In addition to their wide-width excavator, our Dragline Excavators also come equipped with advanced technology that enables them to perform complex tasks with ease. These include automatic tracking, which ensures the vehicle stays on course during excavations, as well as real-time monitoring of excavation conditions, such as moisture levels and soil type.

But that’s not all – our Dragline Excavators also feature robust transmission spurs that ensure smooth operation and quick handling. With a maximum weight capacity of up to 50 tons, these spurs allow the excavator to move with ease and versatility.

Furthermore, our Dragline Excavators are built to last. Their heavy-duty carbon steel construction ensures durability and longevity, even under extreme operating conditions. And because they’re designed for heavy use, they require minimal maintenance, keeping your project running smoothly.

So if you’re looking for an excavator that can handle any job site, big or small, look no further than our Dragline Excavators. With their impressive reach, advanced technology, robust transmission spurs, and durable construction, they’ll be your go-to excavator for years to come.

(Dragline Excavator Large Long Carbon Steel Forging Machining Transmission Spur large Gear Shaft)

Applications of Dragline Excavator Large Long Carbon Steel Forging Machining Transmission Spur large Gear Shaft

Dragline excavators are powerful machines used for excavation, construction, and other heavy-duty applications. These excavators have unique features that make them ideal for a wide range of tasks, including drilling, excavation, and lifting heavy materials.

One important feature of dragline excavators is their large long carbon steel forging machining transmission spurs. These transmission spurs are designed to provide high performance and efficiency while reducing wear and tear on the machine’s components.

The long carbon steel forging machining transmission spurs are made from high-quality materials and undergo rigorous testing to ensure they meet the highest standards of strength and durability. They are strong enough to withstand the toughest jobs, while also being lightweight and easy to install.

These transmission spurs are essential components of a dragline excavator, and they play a critical role in the overall performance of the machine. By using the correct transmission spurs, you can maximize the excavator’s power and efficiency, allowing it to complete its job faster and with greater accuracy.

In conclusion, the large long carbon steel forging machining transmission spurs are an important component of any dragline excavator. They provide high performance and efficiency, reduce wear and tear on the machine’s components, and help to ensure that the excavator can complete its job safely and effectively. By choosing the right transmission spurs, you can get the most out of your dragline excavator and achieve your construction goals more efficiently.

Company Introduction

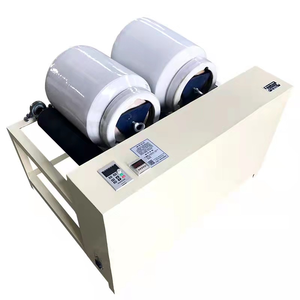

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Dragline Excavator Large Long Carbon Steel Forging Machining Transmission Spur large Gear Shaft

1. What is the difference between a dragline excavator and a regular excavator? A dragline excavator uses a long carbon steel construction for their, while a regular excavator typically has a smaller, more compact design.

2. How many gears does the draglineExcavator transmission Spur have? The draglineExcavator transmission Spur has six gears.

3. Is it safe to drive a draglineExcavator in wet conditions? Yes, it is safe to drive a draglineExcavator in wet conditions as they are designed to operate in water.

4. Are the gears on the draglineExcavator made of high-quality materials? Yes, the gears on the draglineExcavator are made of high-quality materials such as steel, ensuring that they can withstand even the toughest workloads.

5. Can I use the draglineExcavator transmission Spur with other excavators? Yes, the draglineExcavator transmission Spur can be used with other excavators as it is designed to be compatible with most types of excavators.

(Dragline Excavator Large Long Carbon Steel Forging Machining Transmission Spur large Gear Shaft)

REQUEST A QUOTE

RELATED PRODUCTS

CE/ISO9001 Attachment For excavator

Mining dragline Excavator Spare parts Steel Custom Drive large Spline Gear Shaft

61NA-31320 Bucket Adapter Mini Excavator Undercarriage Heavy Equipment Spare Parts

Original and genuine sany equipment parts Quality for sany Excavator spare parts Warranty

Mehaton Heavy Duty Dragline Excavator Spare Parts CNC Machining Hot Long Spur Large Module Gear Rack Product Ring Gears