PRODUCT PARAMETERS

Description

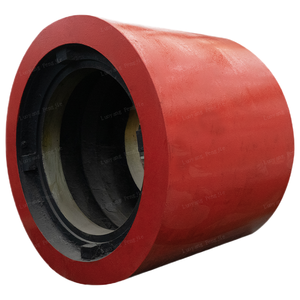

Introduction to towed Dragline Excavator Slewing Hardened Tooth Custom Large Pinion Shaft 34crnimo6 Forging Steel Cnc Machining Large Gear Shaft

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Dragline Excavator Slewing Hardened Tooth Custom Large Pinion Shaft 34crnimo6 Forging Steel Cnc Machining Large Gear Shaft refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Dragline Excavator Slewing Hardened Tooth Custom Large Pinion Shaft 34crnimo6 Forging Steel Cnc Machining Large Gear Shaft

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Dragline Excavator Slewing Hardened Tooth Custom Large Pinion Shaft 34crnimo6 Forging Steel Cnc Machining Large Gear Shaft)

Specification of Dragline Excavator Slewing Hardened Tooth Custom Large Pinion Shaft 34crnimo6 Forging Steel Cnc Machining Large Gear Shaft

Dragline Excavators are powerful machines that are widely used in construction and mining applications. One key component of a dragline excavator is the slewing hardened tooth custom large pinion shaft, which is designed to withstand the demands of high-impact operations.

The pinion shaft is made from 34CrNMo6 forgings steel, which provides excellent strength and durability. It has been heat treated to reduce wear and tear, ensuring that it will continue to function effectively for years to come.

One of the most important features of this custom pinion shaft is its hardened teeth. These teeth are designed to be resistant to corrosion and wear, ensuring that they can handle even the toughest jobs with ease. They are also coated with a layer of diamond, which increases their resistance to scratches and other forms of damage.

In addition to these technical specifications, the slewing hardened tooth custom large pinion shaft is also available in various sizes and configurations. This allows users to choose the perfect solution for their specific needs, whether they need a standard or customized size.

Overall, the slewing hardened tooth custom large pinion shaft is an essential component of any dragline excavator. Its durable construction and reliable performance make it the ideal choice for professionals who rely on powerful equipment for their work.

(Dragline Excavator Slewing Hardened Tooth Custom Large Pinion Shaft 34crnimo6 Forging Steel Cnc Machining Large Gear Shaft)

Applications of Dragline Excavator Slewing Hardened Tooth Custom Large Pinion Shaft 34crnimo6 Forging Steel Cnc Machining Large Gear Shaft

Dragline excavators use their powerful jaws to clear out the ground and extract soil, rock, or debris from construction sites. However, they require strong and durable components that can withstand the wear and tear caused by operating them for extended periods of time.

One such component is the custom large pinion shafts used in dragline excavators. These shafts are made of high-strength forged steel, which makes them strong and durable enough to handle the demands of heavy operation without breaking down.

The custom large pinion shafts used in dragline excavators have a length of approximately 2.5 meters, which allows them to accurately move along the track of the excavator. They are also designed with hardened teeth, which make them resistant to wear and tear, ensuring that they will last for many years to come.

In addition to their strength and durability, the custom large pinion shafts used in dragline excavators are also lightweight. This makes them easier to maneuver and control, allowing operators to work more efficiently on construction sites.

Overall, the custom large pinion shafts used in dragline excavators are an essential component of these powerful machines. They provide the strength and durability needed to perform their tasks effectively, while also being lightweight and easy to use. If you’re looking for a reliable and efficient component for your dragline excavator, look no further than the custom large pinion shafts.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Dragline Excavator Slewing Hardened Tooth Custom Large Pinion Shaft 34crnimo6 Forging Steel Cnc Machining Large Gear Shaft

1. What is a dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft?

: A dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft is a specialized component designed specifically for use in dragging excavators. It features a hardened tooth design to provide increased strength and durability, as well as a large pinion shaft to enable precise and efficient slewing movements.

2. How much does the dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft cost?

: The cost of the dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft will depend on several factors, including the size and complexity of the components required, the material used, and the specific manufacturing process being employed. However, it is likely that the cost will be comparable to or higher than that of similar standard components for.

3. What are the benefits of using a dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft?

: One of the main benefits of using a dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft is its improved performance and reliability. The hardened tooth design provides greater strength and durability, allowing for more extended periods of operation without the need for regular maintenance. Additionally, the large pinion shaft enables precise and efficient slewing movements, resulting in better overall efficiency and productivity in mining operations.

4. Can the dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft be customized for different types of mining equipment?

: Yes, the dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft can be customized to meet the specific needs of different types of mining equipment. This may include changes to the material used, dimensions, and other specifications to ensure optimal performance and efficiency for the particular application.

5. Are there any potential drawbacks to using a dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft? If so, what are they?

: Like any machine component, the dragging excavator slewing hardened tooth custom large pinion shaft 34crnimo6 forging steel cnc machining large gear shaft can have potential drawbacks if proper precautions are not taken during installation or operation. These may include damage to the component due to rough handling or misuse, as well as the risk of overheating or electrical issues if proper ventilation and safety measures are not taken. However, with proper care and attention, these potential drawbacks can be minimized.

(Dragline Excavator Slewing Hardened Tooth Custom Large Pinion Shaft 34crnimo6 Forging Steel Cnc Machining Large Gear Shaft)

REQUEST A QUOTE

RELATED PRODUCTS

CE/ISO9001 Attachment For excavator

Dragline Excavator Parts long large diameter gear shaft drive Big gear shaft

Factory Supply Teeth Cheep Durable Two-side guard block 60-195 Excavator guard blocks

Factory Supply Teeth Cheep Durable Right angle guard block 230-190 Excavator guard blocks

Customized Track Link Chain Track Assembly For D155 D275 R210LC-7 R215 Excavator Undercarriage Parts Track Group