Dragline excavator spare parts

Dragline Excavator Parts long large diameter gear shaft drive Big gear shaft

Undercarriage spare parts For excavator And Bulldozer Undercarriage

Non-standard Forging Gear Shaft Dragline Excavator Parts Large Diameter Gear Shaft Drive Big Heavy Duty Helical Gear Shaft

E10 Series Undercarriage Part Top Carrier Roller Idler Track Bottom Roller Drive Sprocket For Bobcat Mini Excavator Spare Parts

Mehaton Heavy Duty Dragline Excavator Spare Parts CNC Machining Hot Long Spur Large Module Gear Rack Product Ring Gears

Engineering Parts for Repair Parts on Road Milling Machine,Paver, Rollers, Excavators, Loaders Factory Direct For Slaes

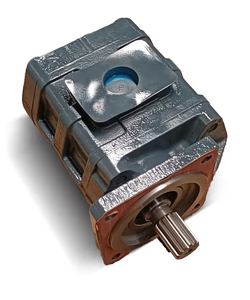

Hydraulic Gear Pump Pilot Pump KX165 Kubota 165 For Excavator Spare Parts

Introduction of Heavy Machinery Mine Dragline Excavator Spare Components

Dragline excavators are substantial makers utilized largely in surface area mining procedures to eliminate overburden or to dig straight for minerals. The spare components for these excavators are crucial for preserving operational performance and security. Key elements include hoist ropes, drag ropes, sheaves, motors, gears, and structural components.

Functions of Heavy Machinery Mine Dragline Excavator Spare Components

- Sturdiness: Created to stand up to severe conditions and hefty tons.

- Precision Design: Makes a specific smooth procedure and decreases damage.

- Safety Standards: Meets strict security regulations for trustworthy efficiency.

- Ease of Installment: Streamlined styles allow for quick replacement and upkeep.

- Material Quality: Created from high-strength alloys and heat-resistant products.

Specifications Table of Heavy Machinery Mine Dragline Excavator Spare Parts

| Part Name | Material | Load Capacity (Tons) | Application Area | Maintenance Frequency |

|---|---|---|---|---|

| Hoist Rope | High-Strength Steel | Up to 50 | Surface Mining | Annually |

| Drag Rope | Steel Alloy | Up to 40 | Coal Mining | Biannually |

| Sheave | Heat-treated Steel | N/A | Quarrying | Every 6 months |

| Motor | Copper Windings | N/A | Civil Engineering | As needed |

| Gears | Hardened Steel | N/A | General Use | Every 3 years |

Applications of Heavy Machinery Mine Dragline Excavator Spare Components

- Surface Mining: Getting rid of overburden products efficiently.

- Coal Mining: Digging deep right into coal seams.

- Quarrying: Removing rock, sand, and gravel.

- Civil Design Projects: Large excavation and building and construction tasks.

Company Introduction

Excavator Attachments specializes in providing high-quality heavy machinery spare parts, including those for ball mills. With a commitment to excellence, they offer durable and efficient solutions tailored to meet the unique needs of their clients. Their extensive product range and customer-centric approach have made them a trusted name in the industry.

5 FAQs of Heavy Machinery Mine Dragline Excavator Spare Components

What is the life expectancy of dragline excavator extra components?

Life span varies by part and operating problems; however typically varies from months to a number of years with appropriate upkeep.

Can I make use of third-party extra components for my dragline excavator?

While possible, making use of OEM (Original Devices Producer) components ensures compatibility and reliability.

Exactly how do I recognize when it's time to replace a component?

Regular inspections and tracking can assist in determining wear and possible failings prior to they become essential.

Are there specific qualifications for dragline excavator spare components?

Yes, lots of parts have to meet sector standards such as ISO or ASME for security and quality control.

Where can I locate reputable distributors for dragline excavator spare parts?

Respectable makers and accredited dealerships are the best sources for premium extra components.