PRODUCT PARAMETERS

Description

Introduction to towed PVD-2B Series PVD-2B-32 PVD-2B-34 Excavator Hydraulic Pump Injection molding machine Spare Parts Piston Assy 3KG FOR PVD-2B-36

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.PVD-2B Series PVD-2B-32 PVD-2B-34 Excavator Hydraulic Pump Injection molding machine Spare Parts Piston Assy 3KG FOR PVD-2B-36 refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed PVD-2B Series PVD-2B-32 PVD-2B-34 Excavator Hydraulic Pump Injection molding machine Spare Parts Piston Assy 3KG FOR PVD-2B-36

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(PVD-2B Series PVD-2B-32 PVD-2B-34 Excavator Hydraulic Pump Injection molding machine Spare Parts Piston Assy 3KG FOR PVD-2B-36)

Specification of PVD-2B Series PVD-2B-32 PVD-2B-34 Excavator Hydraulic Pump Injection molding machine Spare Parts Piston Assy 3KG FOR PVD-2B-36

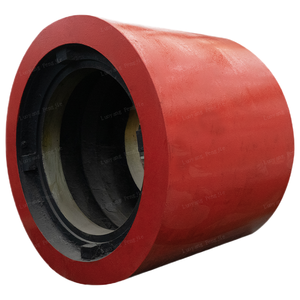

The PVD-2B Collection PVD-2B-32 and PVD-2B-34 excavator hydraulic pumps are precision-engineered components developed for injection molding machines and heavy-duty construction tools. The piston assembly 3KG for PVD-2B-36 is an important spare component making sure reputable efficiency in high-pressure hydraulic systems. Built to satisfy commercial criteria, this piston assembly assurances sturdiness and efficient power transfer sought after operating conditions.

The piston assembly is made from high-strength alloy steel. Warmth therapy and advanced surface finishes enhance wear resistance. This extends the part’s life-span under continuous heavy loads. The design consists of precision-machined grooves and seals. These decrease fluid leakage and preserve consistent pressure levels. Compatibility with PVD-2B-32, PVD-2B-34, and PVD-2B-36 designs makes certain broad application across the series.

Installment is simple. The setting up integrates seamlessly with existing pump real estates and valve blocks. Limited tolerances in making make certain smooth communication with surrounding elements like cyndrical tubes and swash plates. This lowers resonance and noise throughout procedure. Normal maintenance checks are recommended. Examine seals and bearing surface areas for wear to avoid unexpected downtime.

The 3KG piston assembly deals with hydraulic liquids with varying viscosities. It executes reliably in temperature varieties from -20 ° C to 120 ° C. Corrosion-resistant products protect against dampness and chemical deterioration. This makes it ideal for use in extreme atmospheres like mining or building and construction websites.

Secret specs consist of a weight of 3 kgs, a birthed size of 32mm, and a stroke length maximized for well balanced fluid displacement. The assembly undergoes rigorous high quality testing. Pressure biking, lots endurance, and leak detection examinations validate performance. Substitute intervals depend on operating problems. Typical service life varies in between 8,000 and 12,000 hours under normal usage.

Extra parts like the piston assembly 3KG ensure marginal disturbance to equipment procedures. Stocking this component decreases repair work hold-ups. Constantly confirm model compatibility prior to acquisition. Genuine parts assure adherence to initial tools manufacturer standards. Proper lubrication and alignment during installation optimize effectiveness.

The PVD-2B Collection hydraulic pump components are counted on industries calling for precision and reliability. Performance-driven engineering sustains performance in excavation, material handling, and industrial molding applications.

(PVD-2B Series PVD-2B-32 PVD-2B-34 Excavator Hydraulic Pump Injection molding machine Spare Parts Piston Assy 3KG FOR PVD-2B-36)

Applications of PVD-2B Series PVD-2B-32 PVD-2B-34 Excavator Hydraulic Pump Injection molding machine Spare Parts Piston Assy 3KG FOR PVD-2B-36

The PVD-2B Series hydraulic pumps (PVD-2B-32, PVD-2B-34) are critical components for excavators and injection molding machines. These pumps make certain exact control of hydraulic systems. They transfer power effectively, enabling heavy equipment to execute jobs like excavating, training, and material handling. The PVD-2B-36 piston assembly (3KG) is a key extra part designed for compatibility with the PVD-2B Collection. It maintains stress stability, minimizes leaks, and extends devices life expectancy.

These pumps are made use of in building, manufacturing, and auto sectors. Excavators rely upon them for smooth procedure of hydraulic cyndrical tubes and electric motors. Injection molding makers make use of the pumps to maintain constant stress during manufacturing cycles. The piston assembly guarantees accurate product flow, stopping issues in molded products. Its durable design manages high stress and anxiety, making it suitable for constant industrial use.

The PVD-2B Collection pumps include sturdy products. Hard steel components stand up to wear from rubbing and high-pressure conditions. Accuracy machining guarantees limited tolerances, minimizing energy loss. The piston assembly consists of innovative seals to avoid contamination. This lowers upkeep needs and stays clear of unexpected downtime.

Setup is uncomplicated. The pumps and piston assemblies are developed to fit standard hydraulic systems. Replacement parts match initial requirements, ensuring smooth assimilation. Operators can upgrade existing equipment without major modifications. Technical assistance is readily available for repairing and efficiency optimization.

Efficiency screening validates reliability under severe conditions. The pumps maintain effectiveness in temperatures from -20 ° C to 80 ° C. They run efficiently in dusty or moist settings. The piston assembly withstands repeated cycles without deterioration. Normal assessments are recommended to examine seal honesty and part alignment.

Expense financial savings originated from lowered downtime and longer service intervals. The pumps’ efficiency decreases gas usage in excavators. Shot molding makers take advantage of consistent outcome quality, reducing material waste. Bulk investing in alternatives are offered for high-volume individuals. Custom configurations can be requested for specialized applications.

Security standards fulfill global needs. The pumps consist of pressure safety valve to prevent system overloads. Corrosion-resistant finishes secure against chemical direct exposure. Compliance with ISO qualifications guarantees dependability across industries. Customer handbooks give clear standards for procedure and maintenance.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of PVD-2B Series PVD-2B-32 PVD-2B-34 Excavator Hydraulic Pump Injection molding machine Spare Parts Piston Assy 3KG FOR PVD-2B-36

What is the PVD-2B-32 PVD-2B-34 excavator hydraulic pump piston assy 3KG used for? It replaces worn parts in PVD-2B Series injection molding machines. It ensures smooth hydraulic pressure transfer. This keeps the machine running efficiently. Regular replacement prevents breakdowns.

Is the piston assy compatible with PVD-2B-36 models? Yes. The 3KG piston assy works with PVD-2B-32, PVD-2B-34, and PVD-2B-36 machines. The design matches original specs. No modifications are needed. Check machine model numbers before buying.

How often should the piston assy be inspected? Inspect every 500 hours of operation. Harsh working conditions require more frequent checks. Look for leaks, uneven wear, or reduced pressure. Replace immediately if damage is found. Delaying repairs risks machine failure.

What causes piston assy failure in these pumps? Contaminated hydraulic fluid is a common cause. Dirt particles wear down surfaces. Overloading the machine strains components. Poor maintenance speeds up damage. Using non-genuine parts also leads to early failure.

Can the piston assy be installed without professional help? Installation needs technical skill. Incorrect fitting causes leaks or misalignment. Follow the manufacturer’s guide step-by-step. Use calibrated tools for accuracy. For safety, hire a certified technician if unsure.

What materials is the piston assy made from? High-grade steel and durable alloys are used. These handle extreme pressure and heat. Precision machining ensures smooth operation. The materials resist corrosion and wear. This extends the part’s lifespan.

Does the piston assy improve machine performance? It restores original efficiency. Worn parts reduce hydraulic power. Replacing them boosts pressure stability. The machine operates smoothly. Performance upgrades require other modifications.

Are there fake versions of this piston assy? Counterfeit parts exist. Buy from authorized sellers. Genuine parts have serial numbers. Check packaging for official branding. Fake parts fail quickly and void warranties.

How do I store spare piston assy units? Keep them in dry, temperature-controlled areas. Use sealed packaging to prevent rust. Avoid stacking heavy items on top. Follow storage guidelines in the manual. Proper storage keeps parts ready for use.

What if the piston assy doesn’t fit my machine? Confirm the model number matches. Contact the seller for verification. Incorrect parts may be sent by mistake. Return policies usually cover such cases. Never force-fit mismatched components.

(PVD-2B Series PVD-2B-32 PVD-2B-34 Excavator Hydraulic Pump Injection molding machine Spare Parts Piston Assy 3KG FOR PVD-2B-36)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Supply Teeth Cheep Durable Two-side guard block 60-195 Excavator guard blocks

High Quality Volvo Excavator Parts-EC700B EC460B EC360B Coupling Flexible Pump Coupling 4067834 Voe14531075

Construction Machinery Parts Excavator wiring harness E320D 2964617 C6.4 Engine Wire Harness 296-4617

Digger Attachments excavator Rotating Grabber For