PRODUCT PARAMETERS

Description

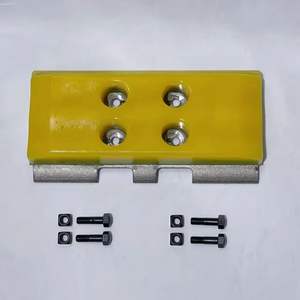

Introduction to towed Wholes Excavator Spare Parts Bucket Pins washer, Pin Shim

A towed excavator, also known as a tracked or tire mobile excavator, is a type of heavy equipment that is widely used in the construction and mining sectors.Wholes Excavator Spare Parts Bucket Pins washer, Pin Shim refers to a variety of parts that are used to maintain, repair, or replace worn-out parts of this machine.

Features and advantages of towed Wholes Excavator Spare Parts Bucket Pins washer, Pin Shim

Durability: made of high-quality materials to ensure long life and high durability.

Compatibility: Designed to meet OEM specifications for a wide range of makes and models.

Economical: Third-party spare parts are usually less expensive compared to OEM parts.

Ease of Replacement: Standardised design allows for quick and easy installation and replacement.

Reliability: rigorously tested to ensure stable and reliable performance.

(Wholes Excavator Spare Parts Bucket Pins washer, Pin Shim)

Specification of Wholes Excavator Spare Parts Bucket Pins washer, Pin Shim

Wholes Excavator Spare Components Container Pins, Washers, and Pin Shims are developed for sturdy performance. These parts connect the container to the excavator arm, guaranteeing smooth operation under severe problems. The pins are made from high-strength alloy steel. This product stands up to wear and contortion. Warmth treatment boosts firmness and longevity. Each pin undergoes exact machining to match specific specs. Resistances are limited to avoid loosening during use.

Washers rest in between the pin and the container. They distribute lots uniformly. This lowers stress on specific parts. Steel washers are hardened to manage high stress. Surface area ending up prevents corrosion and corrosion. Sizes vary to fit different excavator models. Compatibility covers major brands like Caterpillar, Komatsu, and Hitachi.

Pin Shims readjust spaces in between components. They ensure a safe and secure fit as components use gradually. Shims are slim, adaptable, and sturdy. Stainless steel or carbon steel choices are readily available. Thickness ranges from 0.5 mm to 3mm. Personalized sizes can be generated based upon demands.

Production adheres to stringent high quality standards. Raw materials are checked for toughness and make-up. Manufacturing procedures include building, machining, and warm therapy. Each batch is evaluated for flaws. Dimensional checks confirm precision. Tons testing simulates real-world conditions. This ensures integrity in hard environments.

These components work in mining, building, and earthmoving. They handle rocks, dirt, and particles. Regular maintenance with top quality parts expands excavator life. Downtime is minimized when components fit appropriately. Spares are packaged securely to prevent damage during delivery. Supply covers common and specific designs. Bulk orders are sustained for large tasks.

Product accreditations make certain compliance with sector criteria. Traceability is maintained from manufacturing to distribution. Technical support helps consumers pick the ideal parts. Specifications are supplied in comprehensive product sheets. Preparations are brief for basic products. Custom-made orders call for additional processing. Rates are affordable without giving up quality.

(Wholes Excavator Spare Parts Bucket Pins washer, Pin Shim)

Applications of Wholes Excavator Spare Parts Bucket Pins washer, Pin Shim

Wholes excavator extra parts like container pins, washing machines, and pin shims play a key role in heavy machinery. These components ensure the excavator’s digging add-on stays firmly attached to the arm. Pail pins act as the major ports. They deal with heavy loads during excavating, training, and product handling. Regular use causes wear. Top notch pins withstand deformation. This expands the maker’s life-span.

Washers rest between the pin and the excavator’s linkage. They disperse pressure equally. This decreases friction in between moving parts. Much less rubbing means much less warm. Much less heat avoids premature wear. Washing machines likewise keep the pin centered. This avoids misalignment during operation. Misalignment can damage various other parts. Replacing used washing machines very early saves money on fixings.

Pin shims change the fit between the pin and its housing. Over time, voids establish due to use. Loosened parts create resonances. Resonances lower effectiveness. They additionally enhance security dangers. Shims load these voids. This brings back tight resistances. Properly fitted shims lower activity. They make certain smooth procedure. Operators notification less noise and drinking.

These parts are used in construction, mining, and demolition. Harsh atmospheres speed up wear. Dust, rocks, and heavy tons stress parts. Long lasting pins, washing machines, and shims stand up to these problems. Routine upkeep checks spot very early indicators of damages. Replacing components before failure avoids downtime.

Compatibility matters. Parts need to match the excavator design. Wrong sizes or materials cause bad efficiency. Trustworthy providers supply specifications. This makes certain the ideal fit. Purchasing genuine or high-quality aftermarket components assurances reliability.

Operators focus on container teeth and hydraulic systems. Pins, washers, and shims are equally as vital. They keep structural stability. Overlooking them threats costly breakdowns. Equipping these spares decreases repair service hold-ups. Projects stay on routine.

High-strength steel is common for these parts. Warm therapy adds firmness. Coatings protect versus corrosion. Appropriate lubrication during setup lowers initial wear. Complying with producer standards makes certain ideal performance.

These components work together. They maintain the excavator functional under stress. Buying quality parts improves security. It also boosts performance. Devices stays operational much longer. Upkeep prices stay reduced.

Company Introduction

Established in 2007, Excavator Attachments Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Wholes Excavator Spare Parts Bucket Pins washer, Pin Shim

What materials are used in Wholes excavator bucket pins, washers, and shims?

The pins, washers, and shims are made from high-strength alloy steel. This steel is heat-treated for extra hardness. Zinc coating or induction hardening is applied to fight rust and wear. These materials ensure the parts last long under heavy use.

How do I pick the right size for my excavator bucket pins and shims?

Check the excavator’s manual for exact size details. Measure the old parts if replacements are needed. Match the diameter, length, and thickness precisely. Even small differences cause fitting issues. Tolerances are tight for safe operation.

When should I replace bucket pins and washers?

Replace them if you see visible wear, cracks, or bending. Loose pins or unusual bucket movement also signal replacements. Regular checks every 500 hours prevent sudden breakdowns. Harsh conditions might need more frequent checks.

Do these parts work with other excavator brands?

They fit most major brands like Caterpillar, Komatsu, or Hitachi. Compatibility depends on model-specific specs. Compare dimensions with the original parts. Contact the supplier if unsure. Mixing mismatched parts risks machine damage.

What’s the correct way to install bucket pins and shims?

Clean the pin holes first. Insert shims to remove extra space between components. Slide the pin through aligned holes. Secure it with washers and locking bolts. Use torque tools to tighten bolts to the manual’s specs. Lubricate pins regularly after installation. Skipping steps causes early wear.

(Wholes Excavator Spare Parts Bucket Pins washer, Pin Shim)

REQUEST A QUOTE

RELATED PRODUCTS

machining heavy duty dragline excavator spare parts hot long spur large module gear rack

Construction machinery parts VECU Excavator Controller 14594697 14518349 for EC 240B/ NEW 240B

final drive excavator parts TM03 19holes 190 TM04 TM06 TM02 TM18 TM40 Travel motor assy for truck